R319.4 Area wells.

An emergency escape and rescue opening where the bottom of the clear opening is below the adjacent grade shall be provided with an area well in accordance with Sections R310.4.1 through R310.4.4

Local municiple code supersedes national codes.

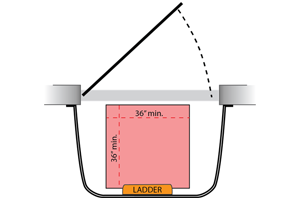

A “means of egress” is simply a basement window that provides an additional way out in case of emergency. Window opening must be a minimum 5.7 sq. ft. and the egress well space must be a minimum 9 sq. ft. Add a LifeStep™ or Corner Step™ egress ladder if the window-well is 44” deep (or more).

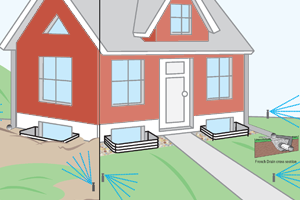

For a successful egress installation, the foundation location needs to be assessed. It is important to check if there is a need to move or relocate amenities.

The foundation wall needs to be in good condition and it is recommended that well placement is at least 3 feet from the foundation corner to maintain structural stability.

Call your local utility provider for location services prior to digging.

Plan for a Succesful Installation

Installing basement egress windows requires a large hole to be cut into the home's foundation. Ensuring you have the necessary equipment is a must.

For creating your egress opening, it is suggested that you hire a foundation cutting professional. A foundation specialist can assess the integrity of the foundation, which is critical when cutting the opening for the window in the foundation.

SPC Tilt N Turn windows are secured to the framed opening by anchor straps (provided). An alternative installation method (less preferred) is to install the window by screws through the vinyl and first wall of steel.

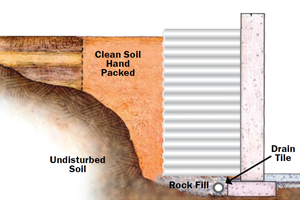

When finishing the exterior of your window installation, prevention of water or moisture intrusion is critical.

Finish your installation by installing an SPC egress ladder and Safe-T-View Cover™.

Sculpt soil and landscape around the egress well to ensure proper water drainage away from the house.

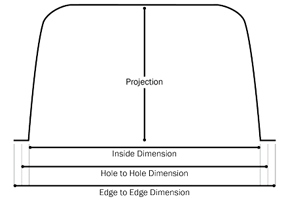

St. Paul Corrugating Company, the originator of steel areawalls, manufactures under the Lux-Right™ brand name the most complete line of areawalls (window wells) and accessories used for basement egress available from any one source. Since 1885 our name has been associated with innovation in metalwork.