An emergency escape and rescue opening where the bottom of the clear opening is below the adjacent grade shall be provided with an area well in accordance with Sections R310.4.1 through R310.4.4

Local municiple code supersedes national codes.

Hot-dip galvanizing (HDG) is often used to protect steel from corrosion in some of the harshest environments imaginable, yet it provides maintenance-free longevity for decades.

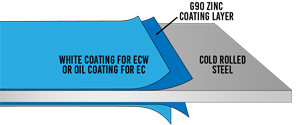

G90 is a grade of galvanized sheet produced to ASTM A653. It has 0.90 oz/sq. ft. of zinc overall or 0.45 oz/sq. ft. per side and has been annealed after galvanizing to produce a surface that promotes good adhesion of paint.

Service Life of Galvanized Steel Articles in Soil Applications

Learn more:

Learn more:

American Galvanizers Association, not-for-profit trade association

To provide maintenance-free corrosion protection for decades, Hot-dip galvanized (HDG) steel is specified for SPC products.

HDG steel will patina over time, changing from the bright shiny silver into a uniform matte gray/silver. It is important to note the durability of galvanized coatings is not determined by the appearance, but rather by the zinc coating thickness.

Regardless of the external appearance of the coating initially, all galvanized pieces will protect steel from corrosion for decades.

St. Paul Corrugating Company, the originator of steel areawalls, manufactures under the Lux-Right™ brand name the most complete line of areawalls (window wells) and accessories used for basement egress available from any one source. Since 1885 our name has been associated with innovation in metalwork.